REVOLUTIONIZE YOUR PRODUCT

New Product Development

Develop the next big thing

Our New Product Development process (NPD) is simple, yet extremely efficient, and results in unique new product concepts.

Every company strives to develop the next big thing: that one future-proof solution that stands out from the competition, meets the market needs, and solves the right problem. But how do you avoid a mainstream solution and create your own blue ocean?

Research-based innovation

The homework for innovation needs to be done properly: define the real problem, know what exists, and map what is happening around you to develop the ideal solution. At Creax, we believe in research-based innovation: key insights in combination with cross-industry creativity and inspiration.

It’s not about a mattress. It’s about understanding sleeping behavior. It’s not about a car, it’s about transporting people.

Identifying and understanding the real problem is a crucial start. That’s why the Creax New Product Development process always starts from key insights. Understanding the dynamics in your domain from a technology, consumer, and competitive perspective leads to the discovery of white space opportunities.

Cross-industry learning

Once we identified the right business opportunities, we apply our toolbox and proven methods to generate creative ideas. The best ideas are combined into breakthrough concepts.

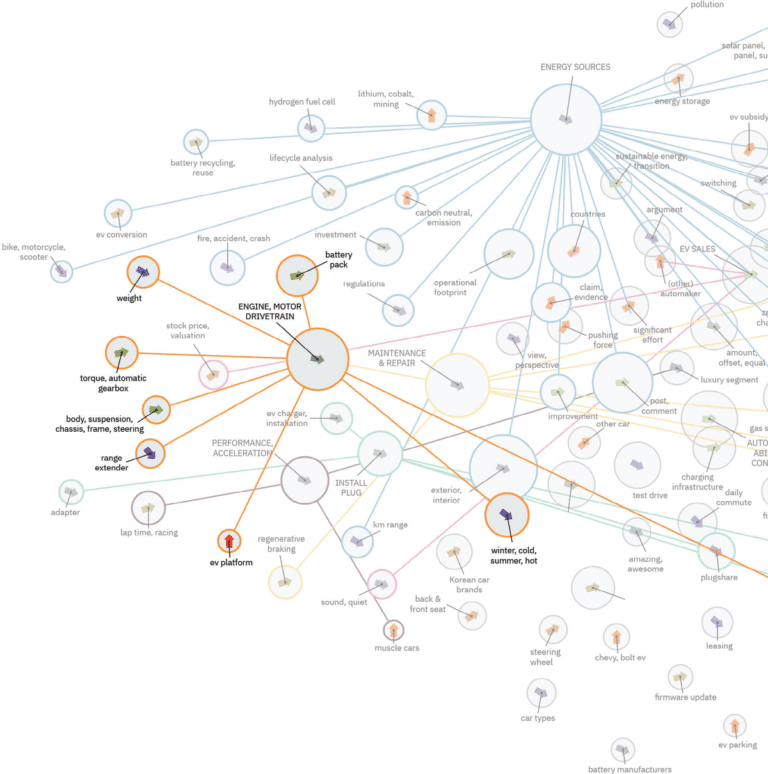

When developing new solutions, the wheel is too often reinvented. Through our multi-disciplinary team, proprietary methodology & tools, and text-mining cross-industry knowledge databases with Artificial Intelligence, we identify what you can learn from others, in and out domain.

These ‘out-of-the-box’ inspirations, ideas, and solutions are matched with your industry-specific expertise. As a result, you get breakthrough concepts and products that distinguish you from your competition.

Revolutionize your product

Interesting insights on new product development

Our collection of articles, insights, and podcasts have everything you need to get started on the topic.

The healthy snack

What is a 'healthy snack'? What about clean label? How can they be made in compliance with existing production processes, and is scalable? A comprehensive…

Cultured meat

Cultured meat. A buzzword or the future? Unbiased insights about research and development activities create confidence to determine a company's position and role in this…

New Product Development, looking beyond Horizon 1

It’s time for the manufacturing industry to roll up its sleeves and re-think its new product development strategy. Refining existing products is no longer enough.

The future of mobility: the drivers behind the steering…

'Minority Report', the best-selling film, envisions urban architecture in 2054 with full 3D mobility and electric vehicles produced in fully automated facilities. Future, or is…

4 ways to make a cheaper electric car

Electric Vehicles (EV) are the future of mobility. But high costs prevent mainstream adoption. We brainstormed 4 creative but practical ways to lower production costs.

Analyzing the plastic soup problem with CRT

The plastic soup is all over the news. A complex problem with many sides and factors. Therefore, it is hard to understand the root problems.…

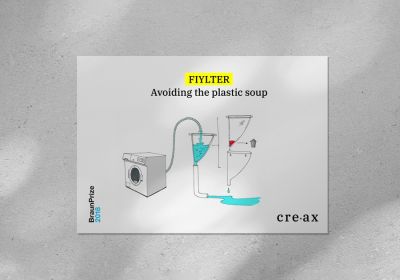

FIYLTER – avoiding the plastic soup

The oceans have become a plastic soup filled with micro plastics. Creax analysed the problem, got creative and came up with a simple but effective…

Trade wars and innovation. How to grab strategic opportunities

A trade war can get your company into trouble surprisingly quickly. To escape the downward spiral strategic innovation brings new opportunities. From a clear and…

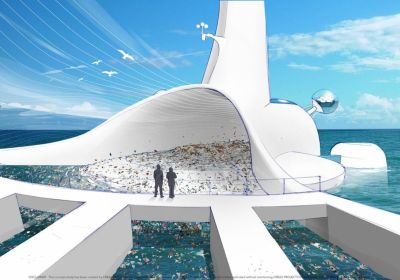

Compîle – plastic soup skimmer

Millions of tons of plastics are floating around in our seas. Marine life often mistakes these plastics for food and chokes on it. The compîle…

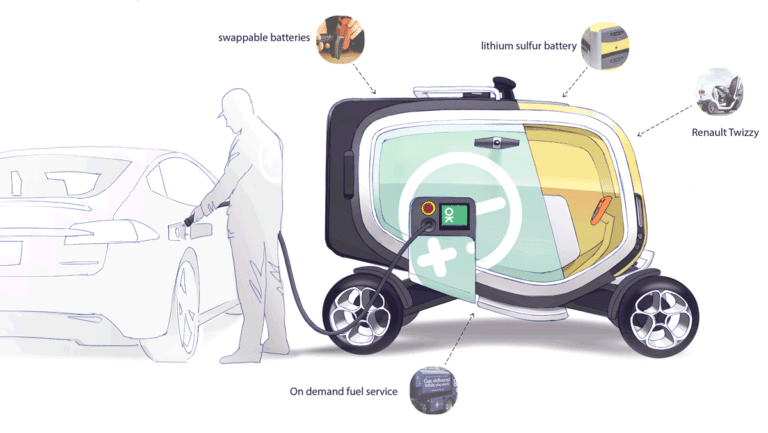

The battery car

The main challenges preventing mass adoption are the limited number of charging stations and long charge times. The Revive ‘battery car’ is a mobile charging…

Futureproof your business

Discover our other services

Creax futureproofs your business by co-creating your innovation portfolio and roadmaps for the short-, mid- and long-term.

Let's get in touch

Develop the next big thing

Ready to revolutionize your product? Discuss your idea with our creatives.